Direct Discharging Vibrating Screen

Direct discharge vibrating screen is mainly for coarse granules sieving or scalping, it is generally equipped with 1 layer, and fine powder will discharged from the bottom outlet. It has the features of large handling capacity.

Model: ZPS-600, ZPS-800, ZPS-1000, ZPS-1200, ZPS-1500, ZPS-1800

Layers: 1-2

Machine Material: Contact Parts Stainless Steel, Full Stainless Steel

Mesh Size: Customized

Description

- Introduction

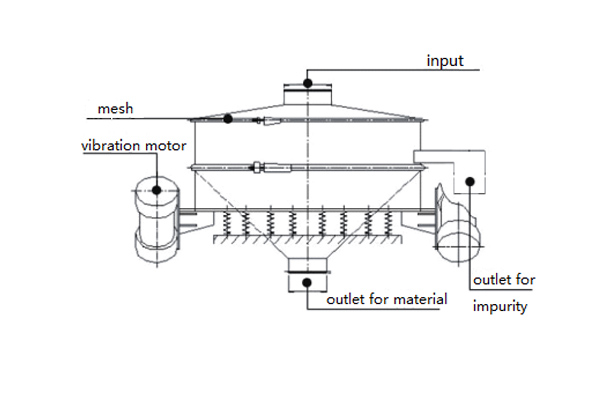

Direct Discharging Vibrating Screen is one kind of round type straight flow vibrating screen separator. It is mainly equipped with 1 layer for 2 different powder size sieving, better performance for coarse powder screening or wet and dry scalping, like wheat flour, washing powder, starch etc . With two vibration motor mounted at both side of the machine as the vibration source and under size outlet downward structure, It has larger sieving capacity then the general rotary vibrating screen. It is ideally suitable for pre-screening in many food and pharmaceutical industry and easy to compound the production line with bag discharging station for screening of raw ingredients.

- Machine Structure

- Advantage

Simple and compact structure , easy maintenance

High Capacity at 3-5 times output than general screen

High Accuracy at 98% sieving purity

Easy to connect with production line

- Parameters

| Product number | power

(kW) |

Motor speed

(r/min) |

Screen diameter

(mm) |

Dimensions

(mm) |

| ZPS-600 | 2×0.18 | 1460 | Φ560 | 1150×600×550 |

| ZPS-800 | 2×0.18 | 1460 | Φ760 | 1360×800×600 |

| ZPS-1000 | 2×0.25 | 1460 | Φ930 | 1600×1000×700 |

| ZPS-1200 | 2×0.55 | 1460 | Φ1160 | 2000×1200×900 |

| ZPS-1500 | 2×0.75 | 1460 | Φ1430 | 2350×1500×1000 |