39 inches single deck rotary vibrating sieve

2024-06-210815 double deck linear vibrating screen sieve separator

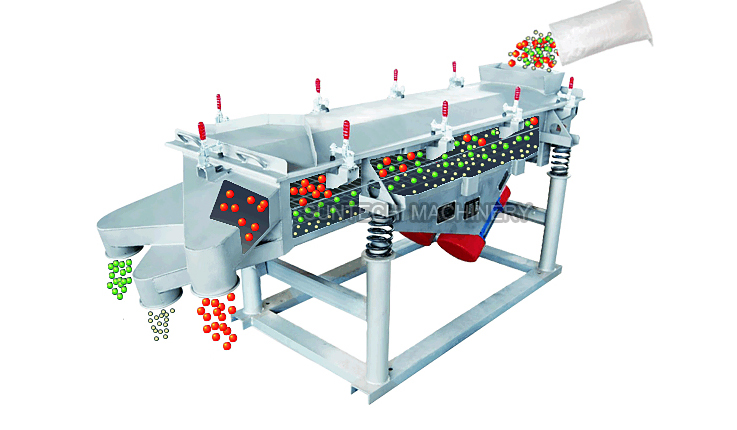

0815 double deck linear vibrating screen sieve separator is the rectangular shape vibrating sieve with two screen layers at size width 800mm length 1500mm. The machine is build in stainless steel with powder coating treatment for the machine surface.It is mainly used for screening, classifying, deblocking, dewatering any lumpy solids or slurries, It can be equipped with single-layer or multi-layer screens, and can continuously screen up to 7 products at a time.

Introduction

Different from the rotary vibrating screen, the linear vibrating screen sieve separator adopt two horizontal vibration motor as the vibration source, which doing the synchronized and reversed rotation and generate the vibration force, the eccentric block on the vibration motor will offset each other parallel to the direction of the motor spindle, superimposing as a resultant force perpendicular to the direction of the motor shaft, thus the movement trajectory of the screening machine is a straight line. The powder or granules materials will jump in straight line on the screen surface and drop down from matching mesh size and discharged from each outlet so that complete the sieving process.

Working Instructions of the double deck linear vibrating screen sieve separator

Two horizontal vibration motor installed under the double deck linear vibrating screen sieve separator

Main Functions

Coarse grading – grading bulk materials that do not require extreme dimensional accuracy

Fine Classification – Provides high precision for particle sizes classifications from less than 3 mm to 50 microns

Dust removal – for extraction of undersized particles

Protective Screening – Used to remove oversize particles, impurities and other foreign materials, etc.

Separation – remove coarse granules from fine powder

Dewatering – used to filtering out solids from liquid

Extraction – Used to remove insoluble impurities from washing and carrier liquids.

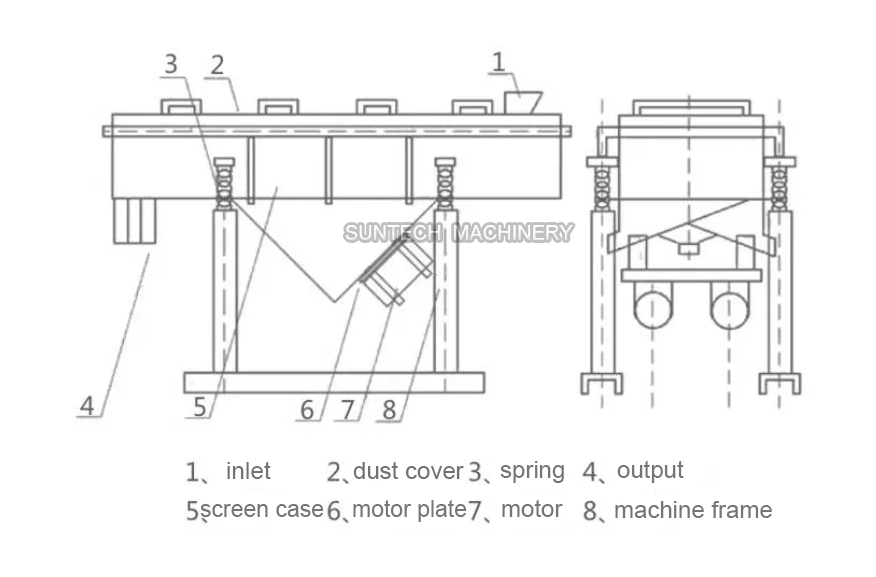

Machine Structures

The general version of 0815 double deck linear vibrating screen sieve separator is mainly composed of the feeding inlet, dust cover, vibration motor, machine case, screen sieve, spring, supporting leg etc. We support any kinds of customized design to meet different user’s needs, like add the movable wheel, feeding inlet with funnel, special outlet direction design, different construction materials, wooden screen sieve, iron screen sieve, the bouncing ball etc.

Detail Machine pictures of 0815 double deck linear vibrating screen sieve separator

Stainless steel screen sieve mesh with strong screen frame

Top layer at 8mm aperture size, bottom layer at 7mm aperture size screen.

Discharging outlet with downward directions.

Main Applications

linear vibrating screen sieve separator can be equipped with single-layer or multi-layer screens, and can continuously screen up to 7 grades products at a time. As it with the features of high screening accuracy, large sieving capacity, simple structure, low energy consumption, low noise, long screen life, good sealing structure, very little dust spillage, easy maintenance, can be used by single machine or for automated operations in assembly line production, So it is widely used in the screening of dry powdered or granular materials in the chemical, food, plastic, medicine, metallurgy, glass, building materials, grain, fertilizer, abrasive, ceramics and other industries.

Working Video

Main Specifications

| Model | Sieve Size(mm) | particle size | Screen surface inclination

(°) |

amplitude

(mm) |

layer(s) | power(kw) |

| ST520 | 500×2000 | 0.074-10 | 0°-10° | 3-8 | 1-7 | 2×(0.37-0.75) |

| ST525 | 500×2500 | 2×(0.37-0.75) | ||||

| ST530 | 500×3000 | 2×(0.55-1.1) | ||||

| ST535 | 500×3500 | 2×(0.55-1.1) | ||||

| ST1020 | 1000×2000 | 2×(0.55-1.1) | ||||

| ST1025 | 1000×2500 | 2×(1.1-1.5) | ||||

| ST1030 | 1000×3000 | 2×(1.1-1.5) | ||||

| ST1035 | 1000×3500 | 2×(1.5-2.2) | ||||

| ST1040 | 1000×4000 | 2×(1.5-2.2) | ||||

| ST1225 | 1200×2500 | 2×(1.5-2.2) | ||||

| ST1230 | 1200×3000 | 2×(1.5-3) | ||||

| ST1235 | 1200×3500 | 2×(1.5-3) | ||||

| ST1530 | 1500×3000 | 2×(2.2-3) | ||||

| ST1535 | 1500×3500 | 2×(2.2-3) | ||||

| ST1540 | 1500×4000 | 2×(2.2-4) |

You must be logged in to post a review.

Reviews

There are no reviews yet.