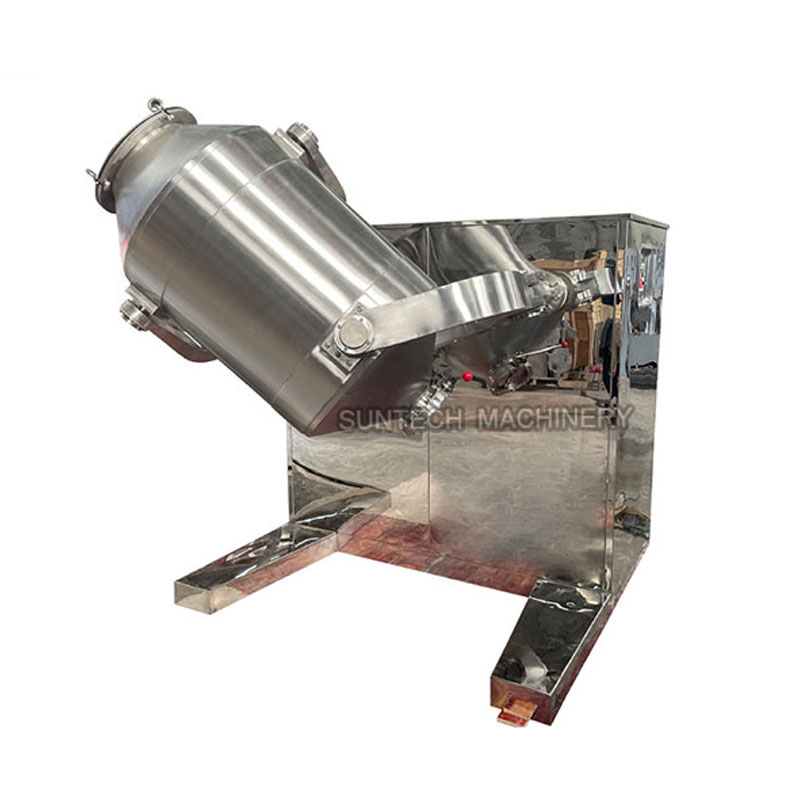

Three Dimensional Mixer

Three Dimensional Mixer blending machine is widely used to mix various powder and granule of good fluidity in different industries,like chemical, food, metallurgy, light industry and scientific research etc .

Volume: 5L, 100L, 200L, 400L, 600L, 800L, 1000L, 1500L

Material: Stainless Steel S304, 316L

Surface Treatment: Mirror Polishing, Sand Blasting

Description

- Introduction

Three Dimensional Mixer blending machine is widely used to mix various powder and granule of good fluidity in different industries,like chemical, food, metallurgy, light industry and scientific research etc .

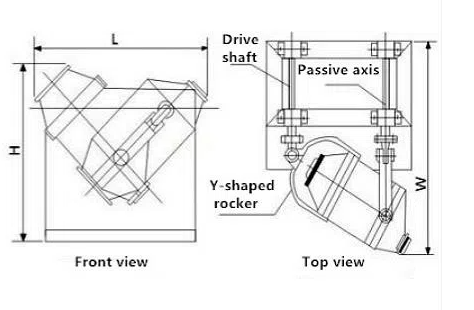

Driven by the active shaft,our mixer makes repeated combination motions of rotating,and tumbling to promote the three-dimension composite movement of the material along the cylinder. Under the unique mixture movement,the flow and diffusion of various materials are accelerated during the mixing process,meanwhile,3D mixer avoids the separation and accumulation of specific gracity of materials caused by the centrifugal force.

- Machine Structure

- Advantage

The machine can perform a very uniform mixing of power or granule materials with a good mobility.

Because the mixing tank rotates in multiple directions, there is no centrifugal force acting on the material, as well as no phenomena of gravity segregation, delamination and accumulation of materials so the mixing rate can be up to 99.9%.Therefore, it is an ideal product currently compared with other various mixers.

The tank has high loading rate max.80% , so that its mixing efficient is high and short mixing time.

The barrel transitional radius everywhere, and also has been polished ,which can meet GMP quality standards.

- Parameters

| Type | Material barrel volume (L) | Max loading volume (L) | Max loading weight (kg) | Spindle rotation speed (r/min) | Motor power (kw) | Overall dimensions

(mm) |

Weight (kg) |

| SYH-5 | 5 | 4 | 5 | 24 | 0.37 | 600*1000*1000 | 150 |

| SYH-100 | 100 | 80 | 80 | 15 | 2.2 | 1200*1800*1500 | 500 |

| SYH-200 | 200 | 150 | 150 | 12 | 3 | 1300*1600*1500 | 750 |

| SYH-400 | 400 | 300 | 200 | 10 | 4 | 1500*2200*1500 | 1200 |

| SYH-600 | 600 | 450 | 300 | 10 | 5.5 | 1850*2500*1650 | 1500 |

| SYH-800 | 800 | 600 | 400 | 10 | 7.5 | 1900*2400*2100 | 1650 |

| SYH-1000 | 1000 | 750 | 500 | 10 | 11 | 1950*2500*2400 | 1800 |

| SYH-1500 | 1500 | 1200 | 750 | 10 | 18.5 | 2600*2500*2350 | 250 |